In the same period, Indian and Vietnamese textile exports dipped by 6 per cent and 10 per cent, respectively.

At about the same time, Chinese scientists, with government and industry support, introduced artificial intelligence and 5G to Xinjiang’s mills, according to a peer-reviewed paper published earlier this month by the Chinese academic journal Textile Technology.

The technologies slashed energy use and improved quality, boosting Xinjiang cotton’s global competitiveness, said the project team, led by senior engineer Huang Kehua, in the paper.

“The sweeping and efficient digital connection brings a revolutionary shift to the manufacturing process, making it smarter and more productive,” according to the team.

Xinjiang’s factories had already automated cotton spinning before the sanctions. But while the machines handled every step of the process, they operated independently and relied on human supervision, according to the paper.

The scientists found that malfunctions, downtime and other vital data and events were recorded manually, while quality assurance also relied on random manual checks because of the high output volumes.

EU sees 200% surge in Xinjiang imports despite human rights concerns

EU sees 200% surge in Xinjiang imports despite human rights concerns

Electricity bills, based on overall consumption, were paid monthly by the factories, without much consideration for how efficiencies could be achieved. But efficiency gains were also hampered by the reliance on manual machine management, they said.

According to European Parliament data, textile factories worldwide account for 10 per cent of total greenhouse gas emissions – second only to the petrochemical industry, and more than aviation and shipping combined.

Huang and his colleagues said there was a huge potential to increase the market appeal of Xinjiang’s textile products by reducing the energy consumption of the factories where they were made.

Their first step was to use 5G technology to connect all of a factory’s machines, not only the spinning machinery but also other energy-consuming equipment such as air conditioners and air purification systems.

Because of 5G’s swifter speeds compared to conventional wireless technology, it supports more connections and drastically cuts data transmission delays – paving the way for AI to oversee the factory’s entire operation.

The researchers said that in a typical Xinjiang textile factory today, AI was monitoring every spindle rotation to alert operators or maintenance staff to inspect potential problems identified by vast data gathering from sensors.

Because it continually learned and improved, AI could boost energy efficiency by coordinating devices and identifying any with unusually high consumption, cutting monthly power use by more than 1 per cent, the paper said.

With AI also overseeing the quality of every yarn, intervening to prevent any flawed strands from progressing to the next stage of production, the “brain system” had achieved “global control of the factory”, Huang and his colleagues said.

US panel asks State Department to set Xinjiang travel advisory at highest level

US panel asks State Department to set Xinjiang travel advisory at highest level

According to the paper, China Unicom, one of the country’s telecommunications giants, is providing substantial support for the technological advancements in Xinjiang’s textile sector.

In contrast to other countries – where 5G technology is rarely used in factories – mainly because of its high cost, China’s extensive construction of 5G base stations and rapid technological advances have significantly reduced the expense.

A cutting-edge 5G IoT communications module in China is now priced as low as 65 yuan (US$9), a fraction of the cost compared to similar products available in Western markets, according to industry data.

The transformation of Xinjiang’s textile industry represents just part of the broader upgrade taking place across the region’s entire industrial landscape.

China’s state grid expects Xinjiang’s renewable energy generation capacity to surpass fossil fuels by the end of this year – thanks to rapid development of solar and wind power – providing cheap, clean energy for manufacturing and AI computing centres.

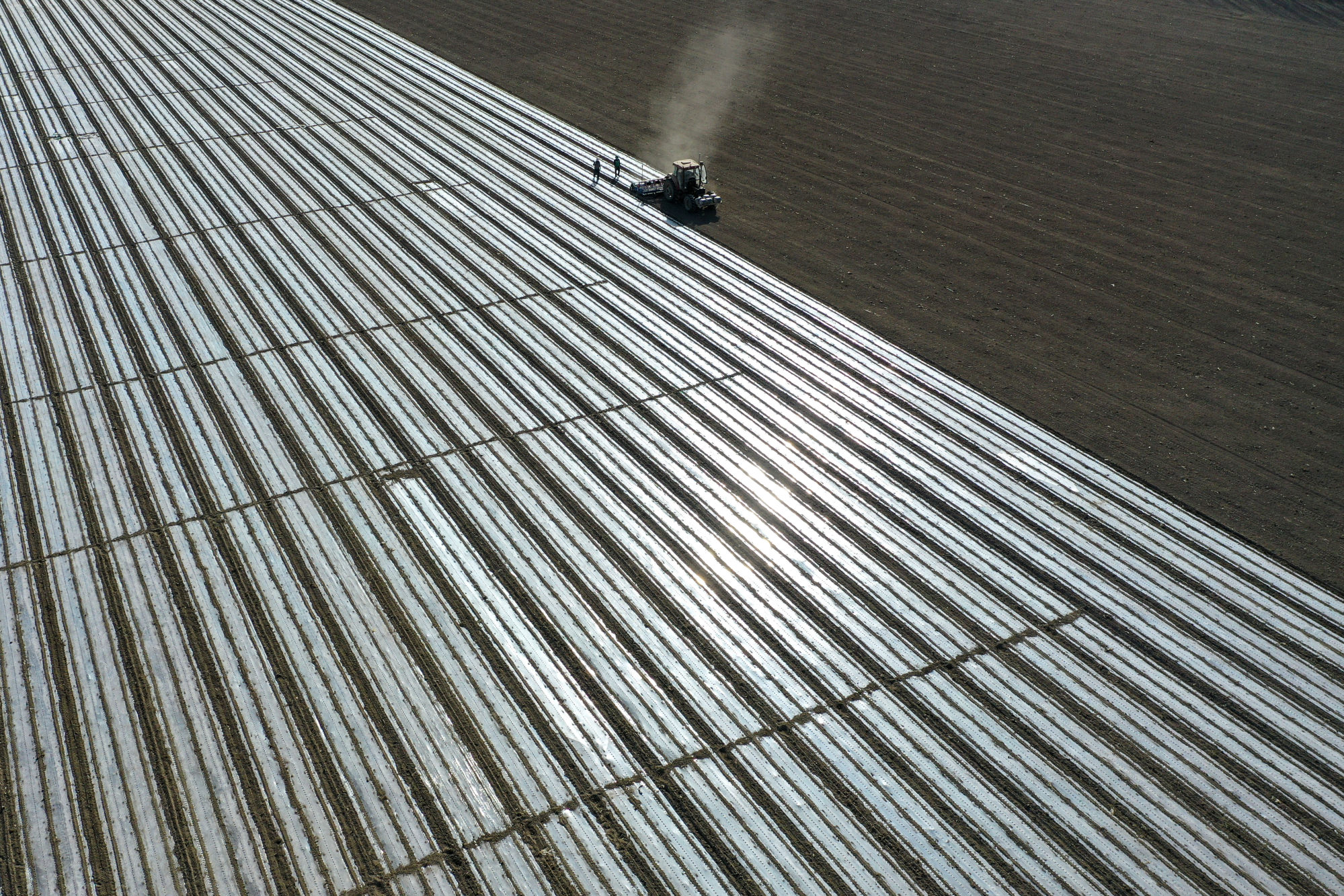

Automated planting and harvesting have been adopted in nearly all of the region’s cotton fields, while drones are further improving crop quality through pest monitoring and pesticide application, local media has reported.

Despite a gradual decrease in the total area of its cotton fields over the years, Xinjiang’s output has increased as a result of these technological advancements, according to the reports.

Xinjiang, the largest provincial-level administrative region in China, produces more than 90 per cent of China’s cotton, and a quarter more than the entire output of the United States.

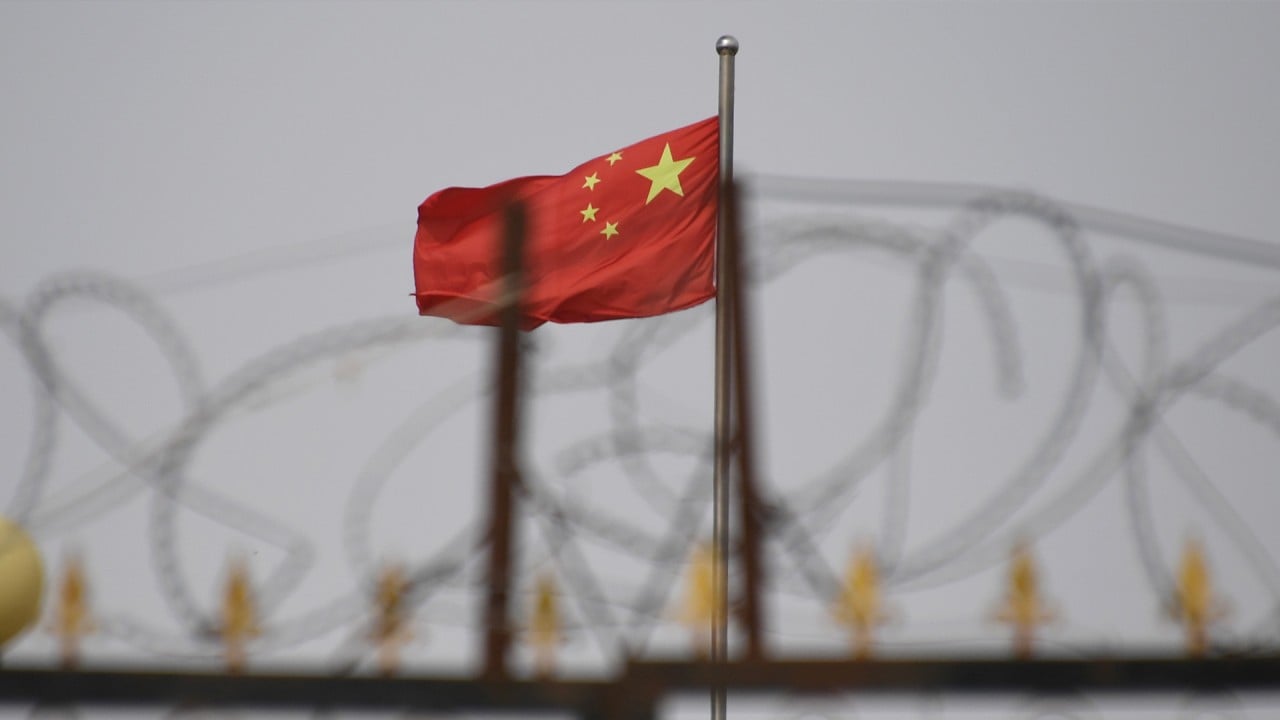

According to the US Labour Department, “it is possible that hundreds of thousands of workers are being subjected to forced labour as part of this [expansion of Xinjiang’s textile industry]”.

“Uygur detainees work as forced labourers to produce textiles. They receive little pay, are not allowed to leave, and have limited or no communication with family members,” the department said on its website.

China leads improvements in fossil fuel engine efficiency to fill electric gap

China leads improvements in fossil fuel engine efficiency to fill electric gap

The US government alleges that Xinjiang cotton products may involve forced labour and lawmakers are considering a new round of sanctions on popular Chinese fast fashion retailers.

Republican Senator Marco Rubio this month called for an investigation into Shein, a Hong Kong-backed fashion retailer, and e-commerce firm Temu for potential violations of his Uygur Forced Labour Prevention Act (UFLPA).

In a letter to Homeland Security Secretary Alejandro Mayorkas, Rubio said the companies should be added to the UFLPA entity list if they were found to be in violation of the law.

Also in April, the Chinese government initiated the latest round in its nationwide effort to modernise manufacturing.

According to the Ministry of Industry and Information Technology, projections indicate that by the end of next year, 70 per cent of China’s textile factories will have achieved digital connectivity and completed the AI transformation.