Development of the big innovation that would have made the Model 2 possible is being put on the back burner

- Tesla’s plan to develop a vehicle with an underbody made of a single piece of metal has been put on hold.

- The gigacasting process was supposed to make the Model 2 possible.

- Tesla is in the midst of a cost-cutting effort, as its sales decline, and its share prices shrink.

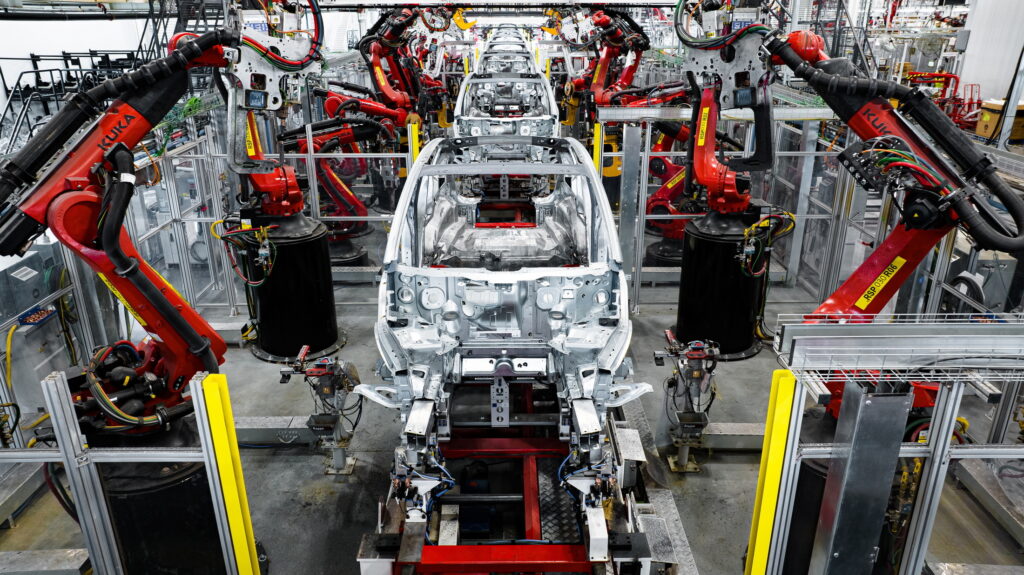

Gigacasting, the process of stamping out large vehicle sections in a single piece, has made Tesla vehicles the envy of the industry. However, according to Reuters, the EV leader is now pulling back on its most ambitious casting project yet.

This news coincides with Tesla confronting declining demand for its vehicles and disgruntled investors following a disappointing first-quarter earnings report. Adding fuel to the fire, Tesla’s abrupt dismissal of its entire Supercharging team on Tuesday further complicates matters for the company.

Tesla had long planned to make the entire underbody of the Model 2 and its upcoming robotaxi out of a single piece of metal, instead of many parts bolted together, as is normal in modern vehicles. The massive structural element was identified as one of the innovations that would make it possible to sell its compact EV for around $25,000.

Read: Tesla’s More Affordable Models Could Be Stripped-Down Versions Of Model 3 And Model Y

However, Tesla has now given up development of the single-piece underfloor, reports Reuters. According to unnamed sources, this decision was made last fall as the company aimed to reduce short-term spending in response to slowing sales. The outlet has also previously reported that development of the Model 2 has been cancelled, although Elon Musk has denied any plans to abandon the creation of the low-cost EV.

Tesla’s gigacasting has been openly admired by competitors like Toyota, whose engineers called the Model Y a “work of art.” Although it makes vehicles cheaper to produce, it requires a big initial investment due to the price of the massive presses and the high engineering costs.

Tesla’s desire to innovate has cost it in the past. It took the automaker years longer than expected to prepare the Cybertruck for production, and the company’s CEO, Elon Musk, said that Tesla “dug our own grave” during development of the stainless steel pickup truck.

But the Cybertruck was designed at a time when Tesla was flush with cash, fueled by surging sales and soaring share prices. However, the automaker’s outlook has dimmed recently, as it fell short of investor expectations in Q1, and its share price has declined by more than 25 percent this year. This downturn may explain why Tesla is now seeking a safer bet.

In addition to pausing development of the single-piece underfloor, the automaker has gutted its supercharger team, and engaged in massive layoffs in recent weeks.